Understanding Eaton Vickers Vane Pumps: Key Models and Installation Guide

Understanding Eaton Vickers Vane Pumps: Key Models and Installation Guide

When it comes to high-performance Vane pumps for industrial Hydraulic Systems, Eaton Vickers is a recognized leader in fluid power technoLogy. Their vane pump series, particularly the 20V, 25V, 35V, and 45V models, are designed for reliability, efficiency, and adaptability across a range of applications—from injection molding and die-casting to heavy-duty hydraulic systems. This article covers essential details about these vane pump models, along with a comprehensive installation guide to help procurement professionals make informed decisions.

Key Eaton Vickers Vane Pump Models and Features

The Eaton Vickers vane pumps are known for their durability and optimized flow characteristics, meeting the demands of various industrial applications. Below are the primary models and their unique characteristics.

1. Vickers 20V Series Vane Pump

- Example Models: 20V8A-1C22R, 20V5A-151C22R, F3-20V5A-1C-22R

- Features: The 20V series is ideal for hydraulic systems requiring efficiency and stable operation under moderate pressures. These pumps are well-suited for light to medium industrial tasks where consistent performance and low maintenance are priorities.

- Applications: Often used in general-purpose industrial machinery, the 20V series balances efficiency with manageable power needs, helping facilities cut down on energy use.

2. Vickers 25V Series Vane Pump

- Example Models: 25VQ21A1C20, 25V21A-1A22R, 25V17A-1C22R, 25V12A-1A22R

- Features: With a slightly higher displacement than the 20V, the 25V series supports increased flow and pressure, making it suitable for more demanding hydraulic applications. These pumps perform exceptionally well in systems where high pressure is required but compact size is also a factor.

- Applications: Widely utilized in hydraulic systems that drive heavy machinery, the 25V series offers a good mix of power and control, ideal for equipment that requires precision without sacrificing flow capacity.

3. Vickers 35V Series Vane Pump

- Example Model: 35VQ30A/38A-1A22R/L

- Features: Known for high speed and high lift capabilities, the 35V series is designed for heavy-load systems. These pumps can handle high pressures while maintaining stable operation, making them suitable for intensive industrial use.

- Applications: Commonly used in construction machinery, mining equipment, and other heavy-duty applications, the 35V vane pump is built to withstand rigorous use, maximizing efficiency in high-demand settings.

4. Vickers 45V Series Vane Pump

- Example Models: 45V60A-1C22L, 45V50A-86C22R

- Features: The 45V series offers large displacement and robust pressure capabilities, making it ideal for large-scale industrial applications. With high output and reliable performance, it is suited for systems that operate under continuous heavy loads.

- Applications: Primarily used in heavy machinery, such as large-scale hydraulic presses and die-casting machines, the 45V series ensures that high-demand industrial environments run smoothly and efficiently.

Installation Guide for Eaton Vickers Vane Pumps

Proper installation of Eaton Vickers vane pumps is essential to maintain their longevity and efficiency. Below is a step-by-step guide on how to install these pumps correctly, ensuring safe operation and extended service life.

Step 1: Inspection and Preparation

Before starting the installation, inspect the pump and its components for any visible damage. Confirm that the model matches the system requirements, and prepare essential tools like wrenches, gaskets, and screwdrivers.

Step 2: Select the Installation Location

Choose a stable, dry, and well-ventilated area for installation. The pump should be installed where it can be securely fastened, with enough room around it for easy access during maintenance. This minimizes exposure to excessive vibrations and prolongs the pump’s operational life.

Step 3: Secure the Pump Body

Using appropriate bolts and nuts, mount the pump on a solid foundation. Ensure the pump is level and that the shaft alignment is precise to prevent bending or twisting. A stable foundation is critical for avoiding mechanical stress, which could lead to premature wear or failure.

Step 4: Connect the Inlet and Outlet Pipes

Ensure the pipes match the pump’s inlet and outlet sizes, and use proper joints for a secure connection. Clean the pipes thoroughly to avoid contamination that could damage the pump’s internals. Additionally, secure connections tightly to prevent leaks, which can reduce efficiency and cause maintenance issues.

Step 5: Electrical Connection

Connect the power and control wires according to the pump’s electrical specifications. Ensure that power cords match the required voltage and follow local electrical safety standards to avoid hazards. Electrical connections must be completed accurately to enable safe, stable operation.

Step 6: Inspection and Testing

Once installed, inspect all components to ensure everything is secure. Perform an initial test run to verify the pump’s performance, checking for abnormal sounds, leaks, or pressure issues. During testing, observe the flow rate and operational parameters to confirm that they meet system requirements. If you encounter any problems, shut down the system immediately and troubleshoot the issue.

Step 7: Routine Maintenance

Regular maintenance is essential for maximizing the pump’s lifespan. Clean the pump periodically, lubricate moving parts, and replace any worn or damaged components. Routine inspections help prevent unexpected breakdowns and ensure efficient operation over time.

Benefits for Procurement Professionals

For procurement teams, choosing Eaton Vickers vane pumps ensures reliable performance and longevity. These pumps are built to meet demanding industry standards, offering a range of displacements and pressures to fit various applications. With models designed for everything from light to heavy-duty hydraulic systems, Eaton Vickers pumps provide an adaptable solution that minimizes downtime and maintenance costs.

Furthermore, Eaton Vickers pumps come with extensive documentation and support, simplifying installation and operation. Their robust construction reduces replacement frequency, resulting in cost savings over time. The pumps’ efficiency also translates to energy savings, an essential consideration for modern facilities focused on sustainable operations.

Conclusion

Eaton Vickers vane pumps are a trusted solution for industries requiring stable, high-performance hydraulic systems. Whether it’s the 20V for moderate applications or the robust 45V for heavy machinery, these pumps offer a tailored fit for nearly any industrial requirement. By following proper installation procedures and maintaining regular service schedules, facilities can ensure prolonged pump life, operational safety, and optimal performance.

For procurement professionals, selecting Eaton Vickers vane pumps means investing in quality, durability, and efficiency—key factors that support seamless industrial operations and contribute to a lower total cost of ownership.

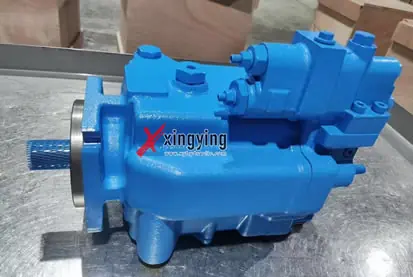

Why Choose XingYing Hydraulic as Your Supplier?

1.Direct from Manufacturer: Benefit from competitive pricing on top-quality hydraulic products, sourced directly from our factory in China.

2.Custom Solutions: Our expertise allows us to tailor hydraulic components to your precise requirements, ensuring optimal performance.

3.Reliable Supply: Count on us as your trusted supplier for consistent quality and timely delivery, backed by our reputation in the industry.