Rexroth hydraulic pump troubleshooting guide

Rexroth hydraulic pumps are known for their reliability, but like any mechanical system, they can sometimes run into problems. Here is a comprehensive troubleshooting guide to solving common problems with Rexroth hydraulic pumps.

Low pressure:

CHECK OPERATION AND VITAL SIGNS: First verify pump operation by evaluating oil pressure and temperature readings. Abnormalities in these readings may indicate a potential problem.

Tighten Connections: Ensure that all plumbing connections are securely tightened. Loose connections can lead to pressure loss.

Check lines for blockages: Use a camera to check lines for signs of blockages, such as kinks or cracks. Use appropriate tools to remove any obstructions.

Clean Internal Components: Use a sandpaper block and cloth to remove rust and dirt from internal pump components to prevent contamination-related pump failure.

Remove plugs and fittings: Remove dirt and debris from plugs, fittings, and connections to ensure smooth fluid flow.

Check for leaks: Inspect hoses and lines for leaks, paying special attention to areas prone to wear. Address any leaks promptly.

Optimize Ventilation Procedures: Modify ventilation procedures in anaerobic areas to prevent cLogging and condensation from forming in tank filters.

Inspect Compressor Components: Periodically inspect compressor components such as belts, pulleys, and bearings for signs of wear to prevent mechanical failure.

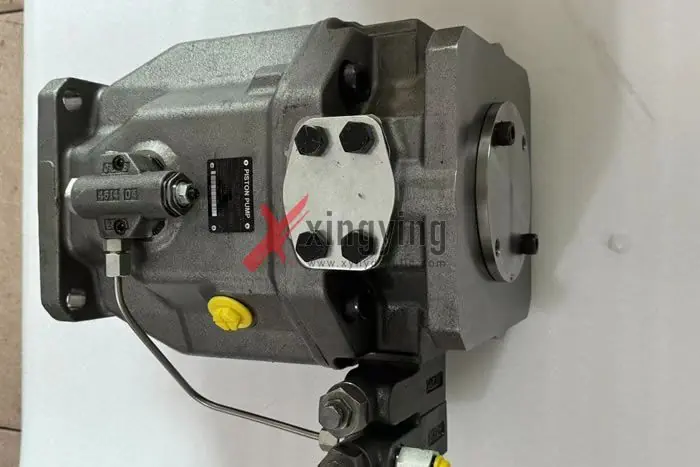

A4VG Rexroth Axial Piston Variable Pump

Noise:

VERIFY OIL LEVEL: Make sure the oil tank is full, as low oil levels can cause pump noise.

Check Installation: Verify that the pump is properly installed and that there are no obstructions preventing its operation.

CHECK FOR DAMAGE: Check the pump for visible signs of damage and replace any damaged parts accordingly.

Oil leaks:

Check seals: Check for worn seals around the pump and replace damaged seals if necessary.

Remove obstructions: Ensure that there are no obstructions between the pump and the tank to facilitate unrestricted oil flow.

Check for leaks: Thoroughly inspect all lines and connectors for leaks and promptly address any observed problems.

CHECK HOSES AND CONNECTORS: Inspect hoses, lines and connectors for damage and replace any damaged components.

Pulsation:

CHECK POWER: Ensure that the power supply is stable and properly connected to the pump.

Check for leaks: Thoroughly check for leaks in the system, as leaks can interrupt pump operation.

Remove clogs: remove any clogs, especially in the impeller, which can interfere with pressure generation.

Test the motor: Verify the function of the motor, as power fluctuations may indicate a problem with the motor.

A10VO45 Rexroth Axial Piston Pump

Sudden loss of pressure:

Check for blockages: Check for any obstructions in the system that could impede fluid flow and cause pressure loss.

Ensure Valve and Pipe Clearance: Verify that all valves and pipes are open and free of debris to prevent flow restriction.

Check wiring and fittings: check wiring and fittings for signs of wear or damage and address any problems found.

Water leaks:

CHECK SEALANT: Check the sealant around the pump inlet point for wear or damage and replace if necessary.

Remove obstructions: remove any debris around the pump area that is blocking the flow of water.

Tighten hose connections: make sure hose connections are tight and free of kinks, replace seals if necessary.

Clear blockages: Check and clear any blockages in the arteries or hoses going to and from the pump.

Check for foam particles: Make sure foam particles are intact and will not cause leaks.

Electrical check: Check for faulty electrical connections and make sure the pump is properly powered.

By performing the following steps, you can effectively troubleshoot and solve problems with your Rexroth hydraulic pump, ensuring optimal performance and longevity.

Why Choose XingYing Hydraulic as Your Supplier?

1.Direct from Manufacturer: Benefit from competitive pricing on top-quality hydraulic products, sourced directly from our factory in China.

2.Custom Solutions: Our expertise allows us to tailor hydraulic components to your precise requirements, ensuring optimal performance.

3.Reliable Supply: Count on us as your trusted supplier for consistent quality and timely delivery, backed by our reputation in the industry.