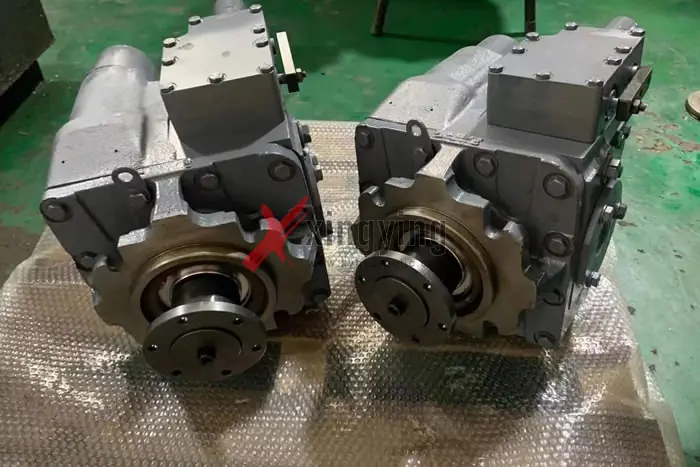

Reasons for severe wear and maintenance of hydraulic pumps

hydraulic pump is the power element of the Hydraulic System, is driven by the engine or motor, from the hydraulic oil tank to inhale oil, forming pressure oil discharge, sent to the executive element of a component. In this paper, Xingdi source machinery to bring the reasons for serious wear and maintenance of hydraulic pumps.

First, the reasons for serious wear and tear of the hydraulic pump:

Hydraulic pump is the power element of the hydraulic system, is driven by the engine or motor, from the hydraulic oil tank to inhale oil, forming pressure oil discharge, sent to the implementation of a component of the element. Hydraulic pump repair from the following three points to find the cause of the failure:

(1) check the internal leakage of the movable arm cyLinder

The simplest excavator hydraulic pump repair method is to raise the movable arm to see if it has obvious free fall. If the drop is obvious, disassemble the cylinder to check, and the seal should be replaced if it is worn out.

(2) check the maneuvering valve

First clean the safety valve, check whether the spool is worn, such as wear should be replaced. If there is still no change after the installation of the safety valve, and then check the manipulation valve spool wear and tear, the clearance limit is generally 0.06MM, wear and tear should be replaced.

(3) Measure the pressure of the hydraulic pump

If the pressure is low, then adjust, add pressure still can not be adjusted up, then the hydraulic pump is seriously worn.

The main reasons that generally cause the movable arm with load can not be lifted are:

1. The excavator hydraulic pump is seriously worn:

The internal leakage of the pump is serious in low-speed operation; in high-speed operation, the pressure of the pump is slightly increased, but due to the wear and internal leakage of the pump, the volumetric efficiency drops significantly, and it is difficult to reach the rated pressure. Hydraulic pumps work for a long time and exacerbate the wear and tear, the oil temperature rises, resulting in wear and tear of hydraulic components and seals aging, damage, loss of sealing capacity, hydraulic oil deterioration, and finally lead to failure.

2, hydraulic components selection is unreasonable:

Boom cylinder specifications for the 70 / 40 non-standard series, seals are also non-standard parts, high manufacturing costs and seal replacement inconvenience. Moving arm cylinder bore is small, is bound to make the system adjusted pressure is high.

3, the hydraulic system design is unreasonable:

Maneuvering valve and full hydraulic steering for a single pump in series, the safety valve regulating pressure points 16MPA, and the rated working pressure of the hydraulic pump is also 16MPA. Hydraulic pump is often under full load or a long time overload (high-pressure) work, and the system has a hydraulic shock, long-term oil change, hydraulic oil contamination, increase the wear and tear of hydraulic pumps, hydraulic pump pump casing cracked (after such failures have been found).

Second, the maintenance of hydraulic pumps:

hydraulic pump maintenance is very important, can effectively extend the use of hydraulic pumps and life.

1. Daily inspection of the product fasteners, such as: screws and other loose, check the installation of piping interfaces, such as oil leakage.

2. Check the cleanliness of the oil seal. Often need to clean the oil seal, to prevent affecting the service life of machinery.

3. Recommended for the first time after 500 hours of work, replace the hydraulic oil, hydraulic oil replacement for the maximum cycle of 2000 hours, with an air filter for the maximum replacement cycle of 500 hours.

4. In order to optimize the service life of hydraulic components, please change the hydraulic oil and filter regularly. Hydraulic contamination is the main cause of damage to hydraulic components. Please keep the hydraulic oil clean during routine maintenance and repair.

5. Daily use should check the hydraulic oil tank oil level to meet the requirements, and at the same time check the water content of the hydraulic oil and whether there is an abnormal odor. Hydraulic oil contains water, the fluid is cloudy or milky, or at the bottom of the tank there are water droplets precipitation. When there is a bad odor in the fluid, it indicates that the working temperature of the hydraulic fluid is too high. When any of the above occurs, change the hydraulic fluid immediately, and find out the cause of the problem and solve it. Check the vehicle for leaks on a daily basis.

6. During commissioning and operation, the Axial Piston Pump components must be filled with hydraulic fluid and purged of air. After a longer period of downtime, oil filling and air venting operations are required because the system may drain oil through the hydraulic lines.

7. Pollution can be fatal to hydraulic components, to ensure that the working environment for maintenance and repair is clean. Thoroughly clean the pump or motor before starting maintenance or repair.

8. Regularly replace the system's hydraulic oil and filters according to recommended standards to ensure efficient and safe operation of the system, and regularly replace wearable parts.

Why Choose XingYing Hydraulic as Your Supplier?

1.Direct from Manufacturer: Benefit from competitive pricing on top-quality hydraulic products, sourced directly from our factory in China.

2.Custom Solutions: Our expertise allows us to tailor hydraulic components to your precise requirements, ensuring optimal performance.

3.Reliable Supply: Count on us as your trusted supplier for consistent quality and timely delivery, backed by our reputation in the industry.