Inspecting the Seals of Rexroth Hydraulic Pumps: A Detailed Guide

Inspecting the Seals of Rexroth hydraulic pumps: A Detailed Guide

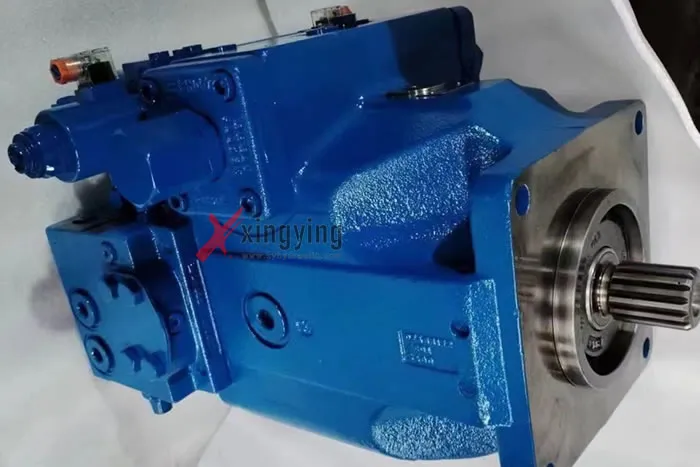

Rexroth hydraulic pumps, like any mechanical equipment, require periodic inspection, especially after prolonged use. Regular checks help prevent accidents, maintain efficiency, and extend the pump's lifespan. One critical aspect of these inspections is the evaluation of the pump's seals, particularly the auxiliary sealing rings. This article provides a comprehensive guide on how to inspect these seals effectively.

Why Inspect Rexroth hydraulic pump Seals?

Hydraulic pumps are subject to wear and tear over time, which can lead to issues such as leaks, reduced efficiency, and potential failures. Regular inspection of the seals ensures that any defects are identified and addressed promptly, preventing more serious problems down the line.

Steps for Inspecting Auxiliary Sealing Rings

1. Surface Examination

- Smoothness and Flatness: Ensure the sealing ring surface is smooth and flat, free from bubbles, cracks, or gaps.

- Uniform End Face: The end face size should be consistent.

- Burr Inspection: For “O” rings, burrs should be trimmed to form a 45-degree angle with the work surface.

2. Hardness Check

- Pressure Consideration: The hardness of the auxiliary sealing ring should match the operating pressure. Higher sealing pressures require higher hardness, while lower pressures allow for softer materials.

- Material Selection: Synthetic rubber is commonly used for auxiliary sealing rings.

3. Size Verification

- Inner Diameter for Cylindrical Surfaces: The inner diameter of the “O” ring should be 0.5-1mm smaller than the outer diameter of the sealing point.

- Dynamic vs. Static Rings: The inner diameter of the “O” ring for dynamic rings should be smaller than that for static rings to ensure a proper seal.

4. Compression Adjustment

- Appropriate Compression: Proper compression is crucial. Too much compression increases friction and makes assembly difficult, while too little compression reduces the sealing effect.

- Compression Rates: For static and dynamic rings, compression should be 8%-23% of the cross-sectional diameter. Smaller diameters should have a higher percentage of compression, while larger diameters should have a lower percentage.

5. Static and Dynamic Ring Considerations

- Anti-Rotation Measures: If the static ring does not have an anti-rotation pin, the “O” ring must handle both sealing and anti-rotation duties. In this case, a larger compression rate is necessary to prevent rotation and ensure a reliable seal.

- Dynamic Ring Compression: For dynamic rings, minimize compression to balance sealing effectiveness with reduced friction and enhanced compensatory movement.

Conclusion

Regular inspection of the auxiliary sealing rings in Rexroth Hydraulic Pumps is essential for maintaining optimal performance and preventing failures. By following the steps outlined above, you can ensure that the seals are in good condition and capable of providing reliable service. Proper maintenance not only extends the lifespan of the hydraulic pump but also enhances its efficiency and safety.

Maintaining a rigorous inspection schedule and addressing any issues promptly will help you avoid costly repairs and downtime, ensuring your Hydraulic Systems operate smoothly and efficiently.

Why Choose XingYing Hydraulic as Your Supplier?

1.Direct from Manufacturer: Benefit from competitive pricing on top-quality hydraulic products, sourced directly from our factory in China.

2.Custom Solutions: Our expertise allows us to tailor hydraulic components to your precise requirements, ensuring optimal performance.

3.Reliable Supply: Count on us as your trusted supplier for consistent quality and timely delivery, backed by our reputation in the industry.