Comprehensive Steps for Analyzing Hydraulic System Diagrams

I. Steps for analyzing Hydraulic System diagrams:

Read and analyze a more complex hydraulic system diagram, roughly according to the following steps:

1,understand the working conditions of mechanical equipment on the requirements of the hydraulic system, to understand the various steps in the work cycle on the force, speed and direction of the three parameters of the quality and quantity requirements.

2,The first reading of the hydraulic system diagram, to understand what components are included in the system, and the executive element as the center, the system is broken down into a number of work units.

3,First analyze each subsystem individually, to understand the relationship between its executive element and the corresponding valves, pumps and the basic hydraulic circuit. Refer to the solenoid action table and the action requirements of the actuator, to clarify the liquid flow route.

4,According to the system of interlocking between the executive elements, synchronization, anti-interference requirements, analyze the connection between the subsystems, a4nd how to achieve these requirements.

5,In a comprehensive reading of the hydraulic system schematic based on the performance of the basic circuit used in the system, the system to do a comprehensive analysis, summarize the characteristics of the entire hydraulic system to deepen the understanding of the hydraulic system.

Hydraulic drive system variety, its application involves machinery manufacturing, light industry, textile, engineering machinery, shipping, aviation and aerospace and other fields, but according to its work, depending on the hydraulic drive system requirements and characteristics of the working conditions can be divided into the following systems.

II, the classification of typical hydraulic systems, working condition requirements and characteristics:

1,speed change-based hydraulic system (such as combined machine tool system,working requirements and characteristics:

1.1, can realize the automatic work cycle of the working parts, high productivity;

1.2, fast feed and work feed, its speed and load difference is large;

1.3, the requirements of the feed speed is smooth, good rigidity, a large range of speed regulation;

1.4, feed the end of the stroke of the repeat position of high precision, there is a strict sequence of action.

2,to the commutation accuracy of the main hydraulic system (such as grinding machine system,working condition requirements and characteristics:

2.1, the requirement of high smoothness of movement, there is a low stabilization speed;

2.2, starting and braking quickly and smoothly, no impact, a high rate of commutation (up to 150 times / min);

2.3, high commutation accuracy, commutation forward residence time is adjustable.

3,pressure change-based hydraulic system (such as hydraulic press system,requirements and characteristics of working conditions:

3.1, the system pressure should be able to frequently change the adjustment, and can produce a large thrust;

3.2, the empty range of speed, pressurized thrust, power utilization is reasonable;

3.3, the system mostly uses a combination of high and low pressure pumps or constant power variable pump oil supply to meet the empty range and pressurization, its speed and pressure changes.

4,a number of executive elements to work with the hydraulic system (such as robotic hydraulic system,working condition requirements and characteristics:

4.1, in the action of the executive elements of the frequent switching, rapid changes in pressure, the system is reliable enough to avoid misoperation;

4.2, can realize the strict sequence of action, to complete the work cycle of the working parts of the provisions of the work cycle;

4.3, to meet the requirements of the speed, pressure and commutation accuracy of each executive element.

Translated with DeepL.com (free version)

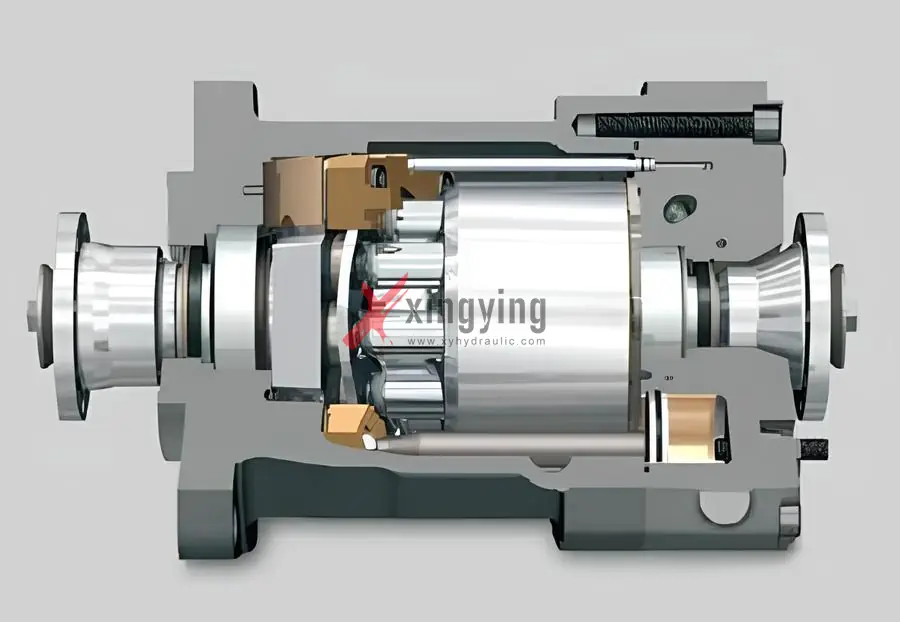

Why Choose XingYing Hydraulic as Your Supplier?

1.Direct from Manufacturer: Benefit from competitive pricing on top-quality hydraulic products, sourced directly from our factory in China.

2.Custom Solutions: Our expertise allows us to tailor hydraulic components to your precise requirements, ensuring optimal performance.

3.Reliable Supply: Count on us as your trusted supplier for consistent quality and timely delivery, backed by our reputation in the industry.