6 Common Hydraulic System Failures and Their Troubleshooting Methods

Troubleshooting Common Hydraulic System Failures

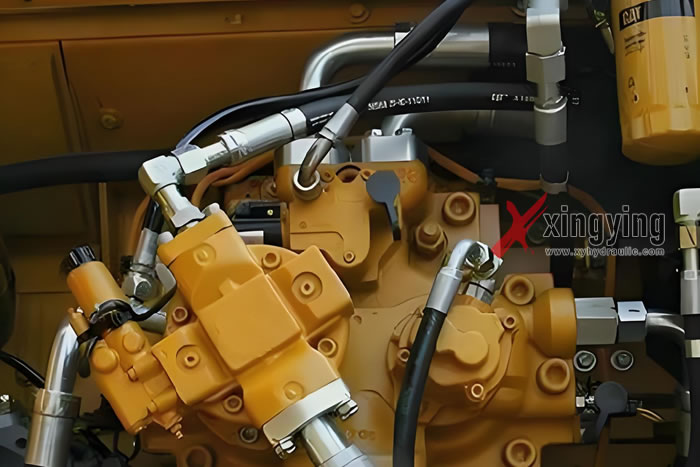

Hydraulic systems are essential in many industrial applications, providing the power needed for various operations. However, like any complex system, they can experience a range of issues. Understanding common hydraulic system failures and their troubleshooting methods can help maintain optimal performance and minimize downtime. This article outlines the typical problems encountered in hydraulic systems and provides practical solutions for troubleshooting.

1. Hydraulic Fluid Leaks

Cause:

Damaged seals, gaskets, or hoses

Loose fittings or connections

Troubleshooting:

Inspect all seals, gaskets, and hoses for signs of wear or damage. Replace any compromised components.

Tighten loose fittings and connections. Use appropriate sealant if necessary.

Regularly maintain and inspect the system to prevent leaks.

2. Overheating

Cause:

Low hydraulic fluid levels

Inefficient cooling systems

Troubleshooting:

Check fluid levels and refill if necessary. Use the manufacturer's recommended hydraulic fluid.

Inspect the fluid for contamination. If contaminated, drain and replace with clean fluid.

Ensure that the cooling system is functioning properly. Clean or replace cLogged filters and radiators.

3. Noisy Operation

Cause:

Aeration (air in the hydraulic fluid)

Cavitation (vapor bubbles in the fluid)

Troubleshooting:

Inspect the system for leaks that could introduce air. Tighten or replace any leaking components.

Check fluid levels to ensure there is no air intake due to low fluid.

Ensure that the pump inlet is not restricted and that the fluid reservoir is adequately vented.

4. Slow or Erratic Movement

Cause:

Clogged filters or strainers

Worn or damaged components (pumps, valves, actuators)

Air in the hydraulic system

Troubleshooting:

Replace or clean clogged filters and strainers.

Inspect pumps, valves, and actuators for wear or damage. Replace any faulty components.

Bleed the system to remove air pockets.

5. Loss of Pressure

Cause:

Faulty pump

Pressure Relief valve issues

Internal leakage in cyLinders or motors

Troubleshooting:

Test the pump to ensure it is generating the required pressure. Replace if necessary.

Inspect and adjust the pressure relief valve. Replace if it is defective.

Check for internal leaks in cylinders and motors. Repair or replace as needed.

6. Contamination

Cause:

Dirt, debris, or water in the hydraulic fluid

Improper maintenance practices

Troubleshooting:

Regularly check and maintain fluid cleanliness. Use high-quality filters and replace them periodically.

Implement a strict maintenance schedule, including fluid analysis and contamination control measures.

Ensure that all hydraulic components are clean and properly sealed.

Conclusion

Effective troubleshooting of hydraulic system failures involves regular maintenance, thorough inspections, and prompt repairs. By understanding the common issues and their causes, you can implement proactive measures to keep your hydraulic system running smoothly and efficiently. Regular training for maintenance personnel and adherence to manufacturer guidelines are crucial for preventing and addressing these common hydraulic system problems.

Why Choose XingYing Hydraulic as Your Supplier?

1.Direct from Manufacturer: Benefit from competitive pricing on top-quality hydraulic products, sourced directly from our factory in China.

2.Custom Solutions: Our expertise allows us to tailor hydraulic components to your precise requirements, ensuring optimal performance.

3.Reliable Supply: Count on us as your trusted supplier for consistent quality and timely delivery, backed by our reputation in the industry.